Example 5 : Simulating a single PID-controller

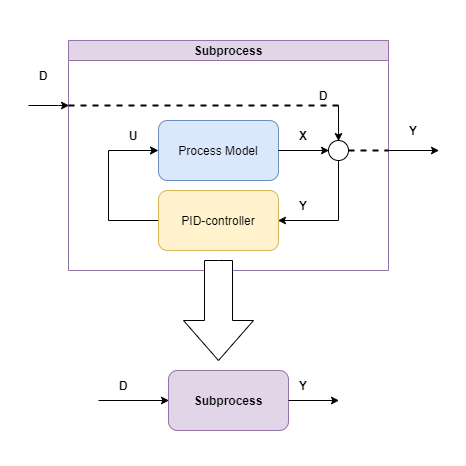

In this example, a step disturbance influences a linear subprocess that is controlled by a PID-controller toward a constant setpoint of y=50, like depicted in the below figure:

SubProcessSimulator.CoSimulateProcessAndPID co-simulates a single PID-controller/processes combination such as this.

UnitParameters modelParameters = new UnitParameters

{

TimeConstant_s = 10,

LinearGains = new double[] { 1, 2 },

TimeDelay_s = 0,

Bias = 5

};

UnitModel processModel

= new UnitModel(modelParameters, "SubProcess1");

var pidParameters = new PidParameters()

{

Kp = 0.5,

Ti_s = 20

};

var pidModel = new PidModel(pidParameters, "PID1");

var sim = new PlantSimulator(

new List<ISimulatableModel> { processModel, pidModel });

sim.ConnectModels(processModel, pidModel);

sim.ConnectModels(pidModel, processModel, (int)INDEX.FIRST);

// create synthetic input data (normally you would get this data from the real-world)

double timeBase_s = 1;

int N = 500;

var inputData = new TimeSeriesDataSet();

inputData.Add(sim.AddExternalSignal(pidModel, SignalType.Setpoint_Yset),

TimeSeriesCreator.Constant(50, N));

inputData.Add(sim.AddExternalSignal(processModel, SignalType.External_U, (int)INDEX.SECOND),

TimeSeriesCreator.Step(N / 2, N, 0, 1));

inputData.CreateTimestamps(timeBase_s,N);

// simulate model over the

var isOk = sim.Simulate(inputData, out var simData);

// plot result

Shared.EnablePlots();

Plot.FromList(new List<double[]> {

simData.GetValues(processModel.GetID(),SignalType.Output_Y),

inputData.GetValues(processModel.GetID(),SignalType.External_U,(int)INDEX.SECOND),

simData.GetValues(pidModel.GetID(),SignalType.PID_U)

},

new List<string> { "y1=y_sim", "y2=u_external", "y3=u_pid" },

timeBase_s, "ex5_results");

Shared.DisablePlots();

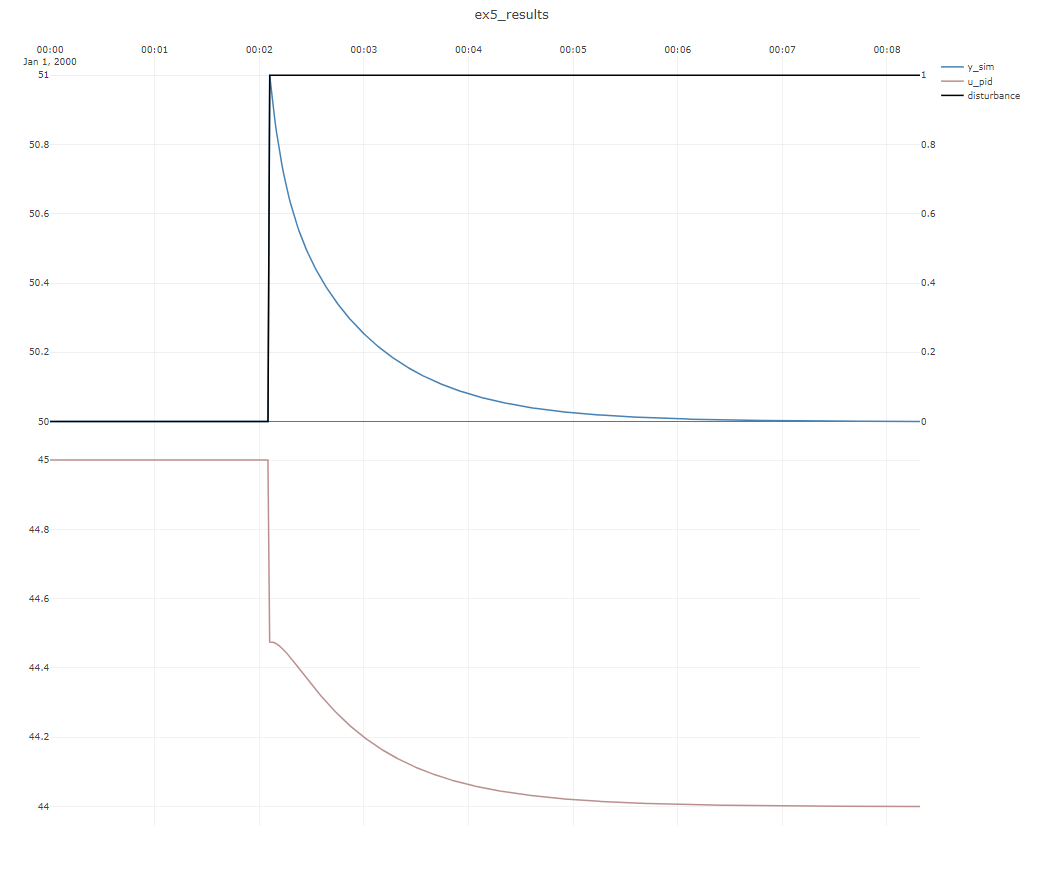

The resulting dynamic simulation:

Note that the PID-controller is able to bring the subprocess back to the setpoint despite the disturbance.

The initial fast response of the proportional term Kp is seen in the plot of u_pid, followed by the gradual

influence of the integral term Ti_s, as is expected.

Note

SubProcessSimulator ensures that the PID/model combination starts in steady-state, so there is no bump or transient in the

start of the dataset.

Note

Normally in industrial settings, PID-controllers are scaled, scaling information can be included by the inputting a PIDscaling to the

PIDModelParameters object on initialization.

Note

CoSimulateProcessAndPID is only intended for simple single-input/single-output pid/model systems. For more general simulation, use ProcessSimulator class.